- About

- History

- Our Responsibilities

- Products

- Downloads

- Contact

VOHUP LEE Concrete Works Sdn. Bhd. has been manufacturing precast products for civil engineering for nearly 20 years. VOHUP LEE multiple manufacturing facilities produce a comprehensive line precast concrete products.

VOHUP LEE strives to keep a clear focus on human needs, managing risk and building reputation into the company’s business decision making. Our team is fully committed to strong growth, profitability and responsible industry leadership.

The follwowing VOHUP LEE products are certified to its respective corresponding standards and accredited by Standards & Industrial Research Institute of Malaysi (SIRIM) and IKRAM QAS.

1. Cement Sand Bricks to BS 6073 : Part 1 : 1981 and BS 476 : Part 22 : 1987

2. Precast Reinforced Concrete Box Culverts to MS 1293 : Part 1 : 1992

3. Precast Concrete Pipes to MS 881 : Part 3 : 1991

60's to 80's From quarry to precast concrete

From its inception, Vohup Lee was in the mineral mining business as a limestone quarry – one of the common materials needed for precast concrete product. Explosive was use for blasting the rock from the hill. Rocks that were collected would be process into limestone. The smaller pieces will be process into 6 inches and 4 inches limestone that can be use for concrete products.

But there was an accident that never had been foreseen—a shaky rock at the top of the hill fell into a rubber estate nearby. Nobody was hurt except that it hit some machineries parked along side the estate when it rolled all the way down to the bottom. The Perak geological department was called upon this matter. After a series of investigation, they concluded that the quarry’s location was unsuitable and stopped the quarrying operation in the early 1980s.

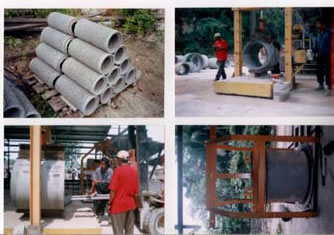

Wohup Lee then was incorporate and changed its name to Vohup Lee Concrete Works Sdn. Bhd. The focus is changed from quarrying operation to manufacturing of precast concrete products. Vohup Lee manufacturing plant started its business with mostly small precast reinforced concrete drain and road curbs that cater for the local market. Then came technology when the company brought in a semi-auto cement sand brick machine.

After operating for 10 years, it’s paved the way for a new era in precast concrete business.

80's to the 90's Setting New Trends

Quality has always been important at Vohup Lee and today's concrete productions are regarded as a benchmark for others to follow. Take, for example, a fully auto cement sand brick machine with build on conveyer belts that turned sand brick production into a trend overnight. But Vohup Lee has always thought like that and back in the 1980s when the company having trouble hiring labors, it hit on the idea of making sand brick with fully auto machinery when sand brick production followed the principle – never try anything new unless it is proven workable!

The '90s, however, were more important as the start of Vohup Lee entry into the bigger market. The Silo cement was introduced in 1993 followed, in 1994, by a MLK cement brick-casting machine, Shark T.K. 20 – long before such items were even heard of by the general manufacture company in Perak Region.

In the end of 1980's, everyone looked to infrastructures works as the next 'big economic boom' and Vohup Lee was no exception as a major producer of cement brick, drains, and box culverts in the Perak region.

In the background, however, changes were afoot. Our nation and the rest of the Asian country were going through economic growth in 1990s. Many places in our nation were going through massive development. Houses, highways, apartments, condominiums and shop lots were built. Vohup Lee made the best out of it by supplying precast concrete products to some major projects around Perak Region.

True enough, there were 'competitive' suppliers at the start of the '80's but they were in poor quality and slow. Vohup Lee supplied cement sand brick produce by fully auto machine which is fast and high in quality during 1995 and have continued to expend of the market ever since.

today The 'Big Bang'

It took a technological breakthrough and a change in the management climate to achieve QAS—quality assurance system that the infrastructure markets are increasingly demanding today. The breakthrough was getting nationwide recognition, QAS, which could supply concrete production to anywhere in Malaysia.

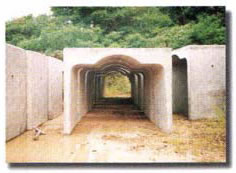

In the end of year 1999, the management goal was set to achieve QAS at year 2001. Vohup Lee met the deadline, thanks to the engineering and the production department. Politics and technology have continued to shape the industry. The '90s saw widespread deregulation, which stimulated competition and customer expectations. Vohup Lee changed too and in 2002 Loh Hang Min, the CEO of Vohup Lee Concrete Works Sdn. Bhd. was to head the entire company into a drastic change. The company divested the non-core operations and focused on super size box culvert in the New Age.

2002 and into the future Vohup Lee is harnessing its experience in quality and experience to generate a startling vision of the future. We welcome change and improvement and can embrace new ideas at great speed. Such characteristics will never change but, as to the rest, the story has only just begun!

Company Responsibility

All around Perak Region, constructors are using Vohup Lee’s product for major government projects. This is supported by the fact that our products are certified by SIRIM QAS, the most recognized certification body in Malaysia, for its quality control system developed for manufacturing a product comply to its respective standards. We employ over 150 people and through doing business with suppliers, partners and trade customer, helps create employment for the nationwide infrastructure industry.

How company responsibility adds value?

All this means that in order to be successful in the future too, we are taking our responsibilities seriously. Because it makes business sense to have sound company ethnics, and because our customer expected it. It makes sense to look after the markets we operate in; to meet anticipate risks; to demonstrate the company value; to work at the employee satisfaction; to improve company efficiency; to meet emerging market needs. We have to earn customer’s trust in its company and products in everything it does, throughout the nation. The responsibility of a company is increasing importance for socially responsible investors, environment-conscious consumers, and ethically aware business partners. And to this end, every single employee plays his or her part in this challenge. Our company responsibility strategy is engage, improve, and be accountable.

- We constantly measure and review our performance in economic, environmental and social issues.

- We engage in customer dialogue and form partnerships that serve the areas we want to improve in.

- We pursue focused and practical improvement programs in relevant organization or geographical areas as part of business operations.

- This involves business planning, internal communications, training.

- We increase accountability to stakeholders through reporting, and informative internal and external communications activities.

What makes it unique is the way we do it. Our company responsibility is developed through logical steps, with much of the work concentrated inside the company, much of the work built on existing programs, and many stages taken forward in parallel.For us, company responsibility is an integral and continuous part of decision-making in all parts of our business; taking responsibility for the consequence of our actions. We believe that by focusing on issues over which we have most influence, we will be able to mobilize more of company resources, be more proactive, and ensure long-term programs.

It is the challenge we take seriously, because it is in the company’s interest and in the interest of our customer.

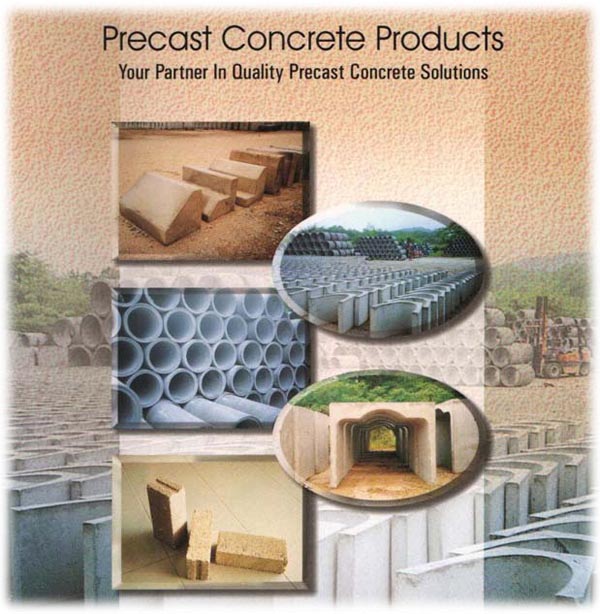

VOHUP LEE has been manufacturing precast products for civil engineering for nearly 20 years. We produce our precast products to buyer's specification.

VOHUP LEE multiple manufacturing facilities produce a comprehensive line precast concrete products including :

Precast Reinforced Concrete Open Drain |

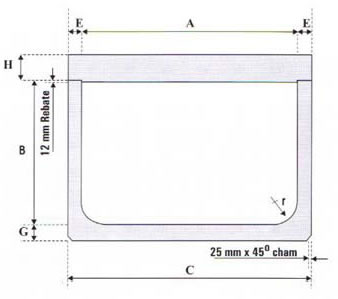

Precast Reinforced Concrete Box Culvert |

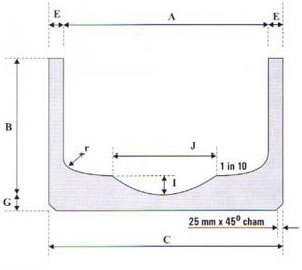

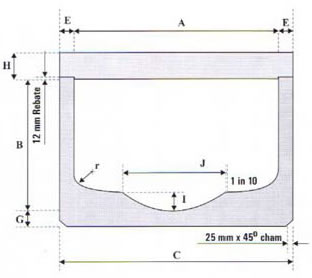

Precast Reinforced Concrete Open Drain w/ Dry Weather Flow (DWF) section |

Precast Reinforced Concrete Box Culvert w/ Dry Weather Flow (DWF) section |

Precast Reinforced Concrete L-Shape Retaining Wall

|

Precast Concrete Pipe Culvert |

Precast Concrete Elliptical/Egg Shape Block Drain

|

Precast Concrete Half-Round Channel Drain |

Precast Concrete Pudu Cut Type Drain

|

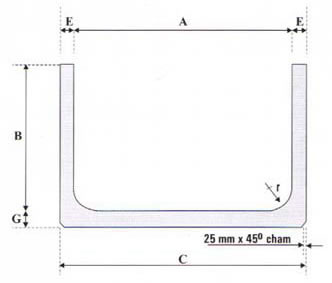

Precast Reinforced Concrete U-Shape Open Drain |

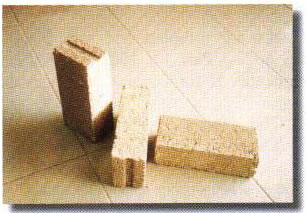

Cement Sand Brick |

Precast Concrete Dustbin Tray |

Precast Concrete Slab |

Precast Concrete Guide Stone |

Precast Concrete Sub-Soil Porous Pipes |

Concrete New Jersey Road Barrier |

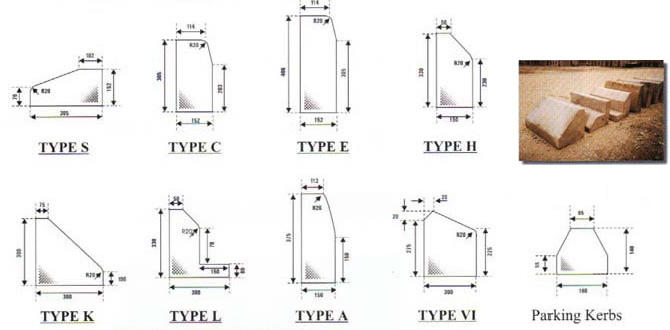

Various Precast Concrete Road Kerbs

Please download our Product Catalogue and Company Profile Catalogue for detailed information on our products and company. You will need Adobe Acrobat Reader to view these files.

Contact Information :

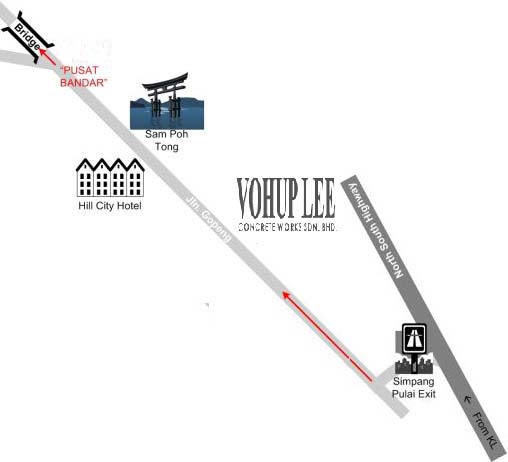

Address : No 5 1/2 Miles, Gopeng Road, Kampung Sengat, 31300 Kampung Kepayang, Ipoh, Perak, Malaysia

Email : vohuplee@tm.net.my, vohuplee@gmail.com

Phone : 05-3571161, 05-3577798, 05 3571290

Fax : 05-3571290

Directions :

Vohup Lee Driving Map ( 4°32'39.11"N, 101° 7'16.77"E )

This webpage is designed to run on Mozilla Firefox & Internet Explorer w/Active X

©Copyrights VOHUP LEE Concrete Works (Malaysia) Sdn. Bhd. 2007